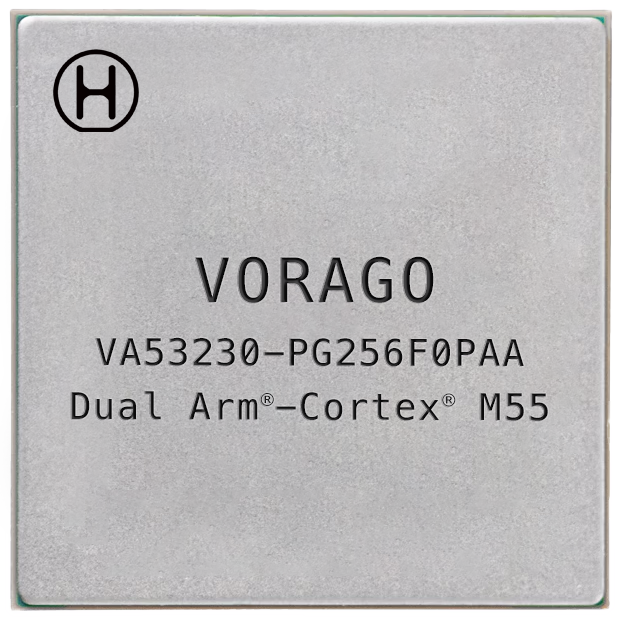

VA5 Family of Rad-Hard and Rad-Tolerant Microcontrollers for Space, Defense, and Autonomous Applications

At a glance:

The VA5 family represents VORAGO’s first generation of dual-core Arm® Cortex®-M55 microcontrollers, available in both radiation-hardened (RH) and radiation-tolerant (RT) versions. Purpose-built for the extreme demands of space, defense, and autonomous missions, these space-grade MCUs combine dual 32-bit cores with robust radiation mitigation, advanced fault tolerance, and power-efficient processing.

The VA5 RH series, engineered with VORAGO’s proprietary HARDSIL® technology, deliver latch-up immunity and maximum resilience in the most severe radiation environments. The VA5 RT series offers extended reliability for missions operating under lower total dose requirements, delivering robust performance without the full requirements of RH designs. The VA5 family of devices address a wide spectrum of mission needs, ensuring dependable operation in the harshest conditions.

Advancing Mission-Critical Control with the VA5 Family

As VORAGO’s first family of dual-core Arm® Cortex®-M55 microcontrollers, the VA5 family brings exceptional performance, security, and reliability to aerospace, defense, and autonomous system applications. Both RH and RT options operate reliably in particle-rich, extreme environments. The RH variant ensures maximum radiation resilience for deep space and long-duration missions, while the RT variant provides a balance of performance and radiation tolerance for less demanding missions.

Enhanced Reliability & System Integrity

Radiation tolerance is matched by the VA5’s architectural safeguards for continuous mission assurance. EDAC-protected SRAM and NVM, and dual watchdog timers plus a recovery watchdog ensure reliability in the most extreme conditions. Designed to integrate securely with spacecraft, defense electronics, and autonomous systems, the VA5 family of space-grade microcontrollers provide the trusted foundation for mission-critical applications that demand both performance and survivability.

Designed for Harsh Environments

The VA5 family is engineered to thrive in radiation-heavy and temperature-extreme environments. Leveraging Dual Interlocking Cells (DICE), Triple-Mode Redundancy (TMR), and robust EDAC with scrub technology, this rad-hard dual-core MCU ensures continuous operation even in deep space missions or high-radiation defense systems.

Superior Control Performance

Featuring dual 32-bit Arm® Cortex®-M55 cores with integrated Floating-Point Units (FPU), the VA5 family provides the processing capability needed for complex real-time control and system management tasks. Its robust peripheral set—including Ethernet MAC with QoS, dual SpaceWire interfaces, motor controllers, and extensive analog and digital I/O—supports applications from satellite altitude control to propulsion management and robotics. With clock speeds up to 200 MHz and low-latency memory access, it delivers efficient performance for deterministic control under harsh conditions—exactly what’s expected from a rad-hard microcontroller built for mission success.

-

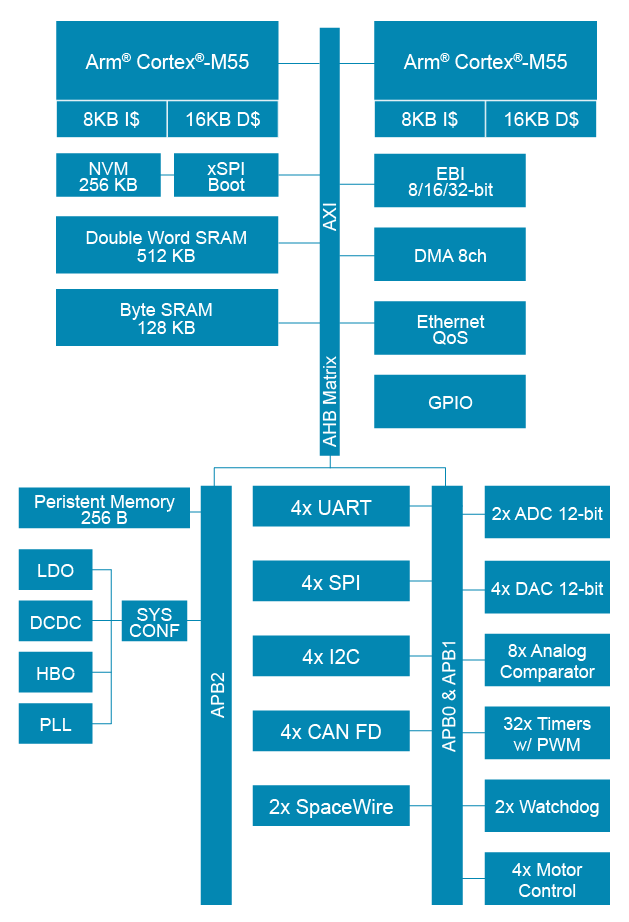

Dual Arm® Cortex®-M55 Cores with Integrated Floating-Point Unit (FPU), Memory Protection Unit (MPU), Serial Wire Debug (SWD) & JTAG

Robust Memory Architecture:

- 256 KB non-volatile memory (NVM)

- 512 KB on-chip double word SRAM

- 128 KB on-chip byte SRAM

- EDAC & scrub engine for error resiliencePeripheral Rich: Ethernet MAC with QoS, 2× SpaceWire, 4× CAN FD, 4× UART, 4× SPI, 4× I²C

Motor Control & Analog/Digital Interfaces: 4× Motor Controllers, ADCs, DACs, comparators, timers, and watchdogs

Temperature Range: –55 °C to +125 °C

Packaging: Plastic 256 BGA or Ceramic 216 QFP

-

These metrics ensure the VA5 remains reliable in high-radiation, particle-intensive space environments. TID ratings quantify its cumulative radiation tolerance, while SEL immunity measures resilience to single, high-energy particle events. Consistent operation under these conditions is crucial for protecting mission-critical data and maintaining long-term reliability.

Radiation Hardened:

Total Ionizing Dose (TID) > 200 krad(Si) with FRAM

Single-Event Latch-Up (SEL) immunity to LET > 110 MeV*cm2/mg

Radiation Tolerant:

Total Ionizing Dose (TID) > 50 krad(Si) with FRAM

Single-Event Latch-Up (SEL) immunity to LET > 60 MeV*cm2/mg

-

Primary Processing – Dual Arm® Cortex®-M55 cores with integrated Floating-Point Units (FPU) deliver efficient real-time control and computation for mission-critical command, control, and sensor processing. Error Detection and Correction (EDAC) with a scrub engine ensures reliable operation in high-radiation environments.

Mission Control & System Management – A versatile set of peripherals—including 4× motor controllers, SpaceWire interfaces, and Ethernet MAC with QoS—enables precise actuation, secure networking, and deterministic control in satellites, spacecraft subsystems, defense platforms, antenna systems, and array controllers.

Fault-Tolerant Data Handling – The VA53230’s EDAC-protected SRAM, non-volatile memory, and External Bus Interface provide safe, high-integrity data storage and transfer for navigation, telemetry, mission planning, and optical control systems.

Analog & Sensor Integration – With dual 12-bit ADCs, 4× DACs, and 8 analog comparators, the VA532XX supports direct interfacing with propulsion sensors, environmental monitors, optical sensors, and power management systems—reducing the need for external components.

Secure Communications & Control Links – Multiple serial interfaces (CAN FD, UART, SPI, I²C) combined with robust watchdog protection enable secure, fail-safe communication for distributed spacecraft control, robotic arms, autonomous defense systems, and software-defined radios (SDR).

-

Engineering Samples: Q3 2026

Development Kits: Q4 2026

Qualification Samples: Q4 2026

Our Brand Promise

Why Choose VORAGO?

Proven Expertise: With 20 years of experience, VORAGO Technologies has a strong track record in delivering radiation-hardened and extreme-temperature solutions. Customers can trust our expertise in tackling the most challenging environments.

Innovative Radiation Hardening Technology: VORAGO's patented HARDSIL® technology offers a cost-effective solution for hardening commercially designed semiconductor components, making it accessible and efficient for customers.

Diverse Application Portfolio: VORAGO has successfully provided solutions across Aerospace, Defense, and Industrial applications. Our extensive portfolio enables customers to Achieve Your Mission in space or closer to home.

Reliability in Hostile Environments: VORAGO empowers customers to explore new design possibilities in even the harshest environments. Our solutions enable equipment to function reliably in extreme the conditions for edge computing ensuring mission success.

Be the first to know about new VORAGO products and services by joining our newsletter.

More Products

VA7230

The VA7230 is a space-grade, radiation-tolerant edge computing microprocessor that packs dual Arm® Cortex®-A72 cores and an integrated 3D GPU into a power-efficient design—offering over 10 GFLOPS of performance along with high-speed interfaces (PCIe, USB 3.0, SATA, TSN Ethernet) and robust security (TrustZone®, secure boot, crypto offload). Certified to MIL-PRF-38535 Class B and MIL-STD-883-1, it's ideally suited for AI, image processing, autonomous navigation, and secure onboard computing in the harshest space environments.

VA41630

The VA41630 is VORAGO’s flagship Arm® Cortex®-M4 microcontroller, built with patented HARDSIL® technology for radiation resilience in space. Featuring integrated FRAM, advanced communication and analog interfaces, QML-qualified reliability, and versatile packaging options, it delivers high-performance control for scientific instruments, motor systems, satellite buses, and payload operations—reducing system cost and size while ensuring mission success in the harshest environments.